| sportspitchdoctor |

|

A Legacy for Cricket - My History of Non Turf Cricket Pitches

To most 1976 may well mean the long hot summer and a drought lasting from the Spring holiday through to September but it also heralded a development by myself that was to change how synthetic turf cricket pitches were perceived and used.

After five years of trials and tests using different combinations of concrete, bitumen and a variety of surfaces had failed to

achieve the goal of producing a cricket pitch that would mimic the performance found on grass an idea was hatched to use a combination of stone and hard porous as a base. Hard Porous had long been used as an alternative to grass for football, hockey and tennis so why not cricket.

So in August a match was arranged between Notts County Officers Cricket Club and an xi from Gedling Borough Council, headed by former England, Nottinghamshire and Yorkshire batsman Brian Bolus who was Chief Executive at the time, to be played on a woven carpet laid in the centre of the hard porous pitch at Carlton Forum Sports Centre.

The match was such a success and the performance so good that it was immediately obvious this was how a pitch suitable for playing competitive cricket could be produced.

After five years of trials and tests using different combinations of concrete, bitumen and a variety of surfaces had failed to

achieve the goal of producing a cricket pitch that would mimic the performance found on grass an idea was hatched to use a combination of stone and hard porous as a base. Hard Porous had long been used as an alternative to grass for football, hockey and tennis so why not cricket.

So in August a match was arranged between Notts County Officers Cricket Club and an xi from Gedling Borough Council, headed by former England, Nottinghamshire and Yorkshire batsman Brian Bolus who was Chief Executive at the time, to be played on a woven carpet laid in the centre of the hard porous pitch at Carlton Forum Sports Centre.

The match was such a success and the performance so good that it was immediately obvious this was how a pitch suitable for playing competitive cricket could be produced.

1st GenerationWith the trial match such a success a purpose built hard porous base was constructed at the County Council Staff Sports ground ready for the 1977 season. This consisted of a foundation stone with hard porous topping and a woven surface. Rubber shockpads were provided at each end to cushion the impact of the bowlers.

The high level of interest and the use feedback during this first season led to great deal of interest in the product and before the end of the season a number of companies were already selling copies of the design. |

Known current products using this design –

Clubturf Natural Pitch Tom Graveney Hard Porous Pitch The NottsTurf Pitch |

2nd GenerationHaving been rushed into use little was known about the long term effects of playing on a base of this kind and very soon it became evident that the carpet alone did not afford protection to the base meaning that at the end of each year the carpet needed to be removed and the surface levelled.

To alleviate this damage an underlay or shockpad was needed in the area of the pitch of the ball to protect the hard porous surface. Initially thin rubber pads were tried but the elastic nature of these meant the playing performance was adversely affected so an alternative was sought and found in the shape of fibre bonded pads, resin bound for extra strength. |

Known current products using this design –

Clubturf International Pitch Total Play tp365 Pitch |

3rd GenerationBetween 1977 and 1981 further problems occurred and it was evident that disturbance of the surface wasn’t the only item that needed attention. Worm infestations created undulations to the surface and natural movement due to climate and moisture led to a mixing of the layers of aggregate.

The mixing had two affects with on occasions some of the larger stone making its way to the surface of the hard porous and with pitches getting faster and bouncier as time went on. To prevent these problems a porous geo textile was introduced to isolate the hard porous material, thereby preventing worm contamination and mixing. |

Known current products using this design –

The “Envelope” system |

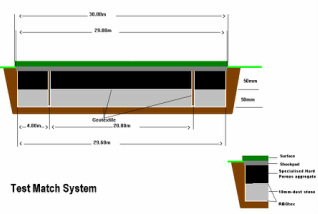

4th GenerationThe only weakness of the Envelope system was that in order to use conventional stumps the integrity of the seal had to be broken to allow stumps to go through the geo-textile lining as the depth of point was greater than the depth of the hard porous aggregate.

Having been involved since the original design my son took this problem on board and utilised two layers of geo-textile to both isolate the base construction, both stone and hard porous, and separate the two layers. This created the depth required to use conventional stumps without cutting the geotextiles. |

Known current products using this design –

The “Test Match” Pitch |

Floodlit Cricket and the birth of a new speciesDuring the early 1980’s Kerry Packer’s World Series cricket

re-introduced the idea of floodlit cricket. Not wishing to be left out cricket in this country was keen to exploit the idea of after work cricket under floodlights. Unlike in Australia where many cricket grounds are shared with Aussie Rules football and have floodlights the only grounds with floodlights in this country were football or rugby grounds and athletic stadiums. My task was therefore to come up with a synthetic pitch that could be installed on temporary basis leving no sign of its presence. The stone and hard porous base was a no go as the soil structure of the grounds could not be disturbed so something to sit on top was required. Work with expanded foam had shown that this material could provide bounce when laid over a firm level base, but being very light it needed to be weighted down. At first, as with the 2nd generation of hard porous pitches, rubber pads were tried, being replaced by a fibre pad when these became available. Whilst this worked for temporary pitches the unstable nature of the foam meant that overtime ripples could develop on permanent pitches. This was solved by laminating the foam on each side to a fibre bonded material, 4-6mm thick on one side and 1-2mm on the other, giving rigidity either side of the foam. Unfortunately the stiff nature of the thicker pad meant that production was difficult and led to a lot of waste material. To solve this it was decided to use two layers of the thinner material to stabilise the foam and lay the thicker pad once again as a separate entity. The design can be installed on consolidated earth or for greater control onto a hard porous base. |

Known current products using this design –

NottsBase system Premier system |